グッドラックビルが業界賞での卓越したパフォーマンスで認められる

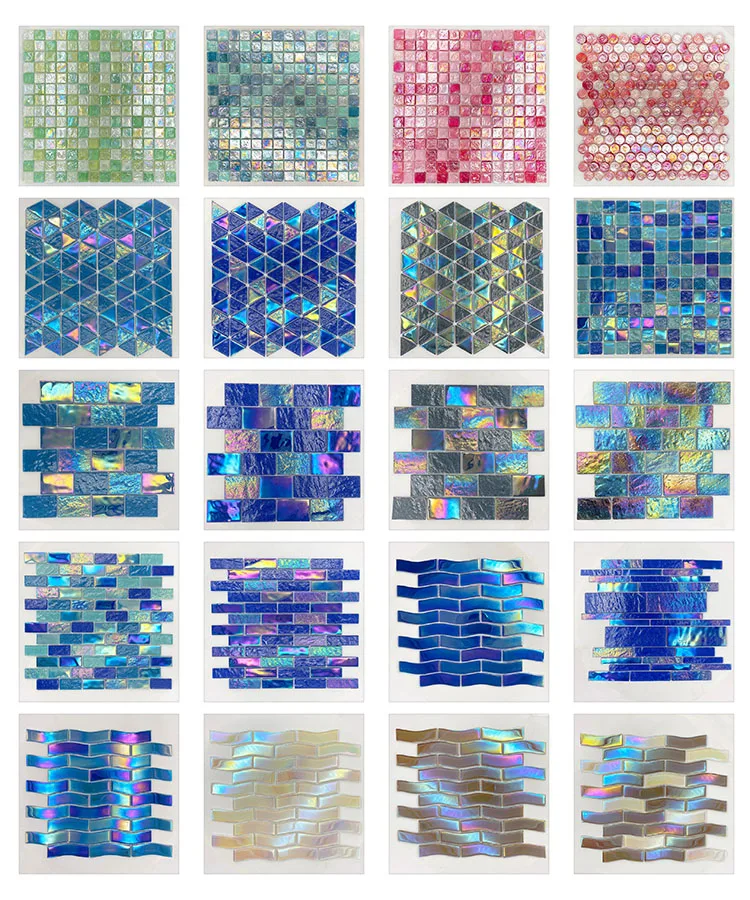

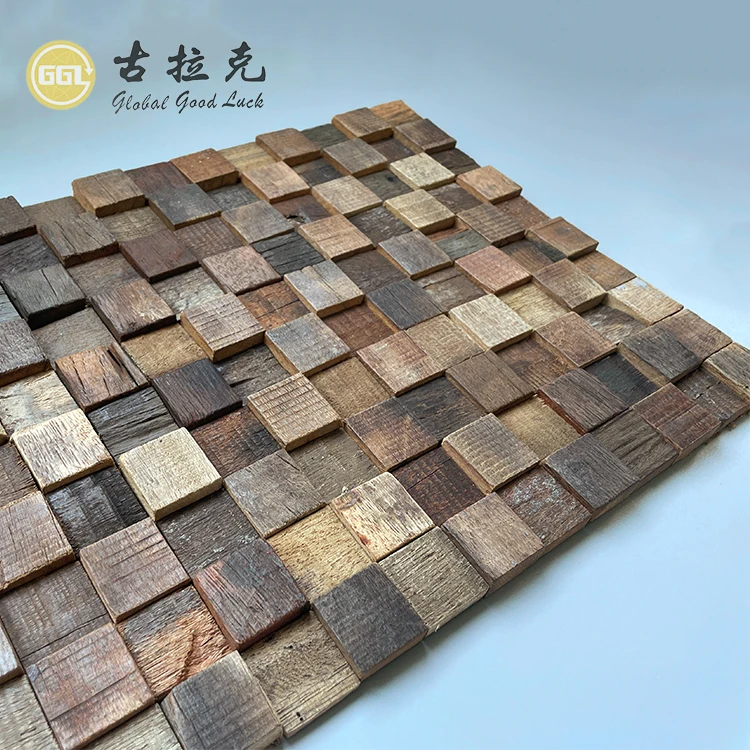

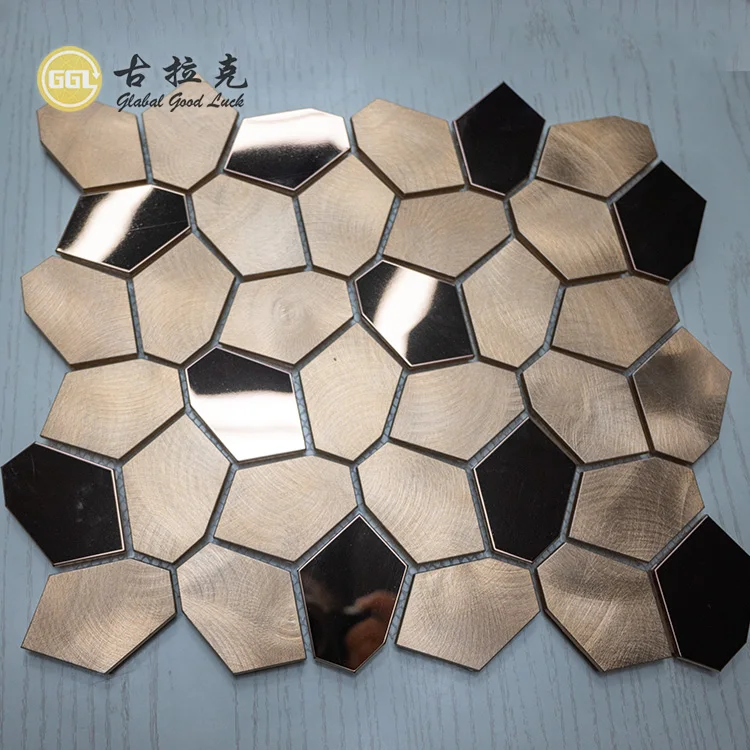

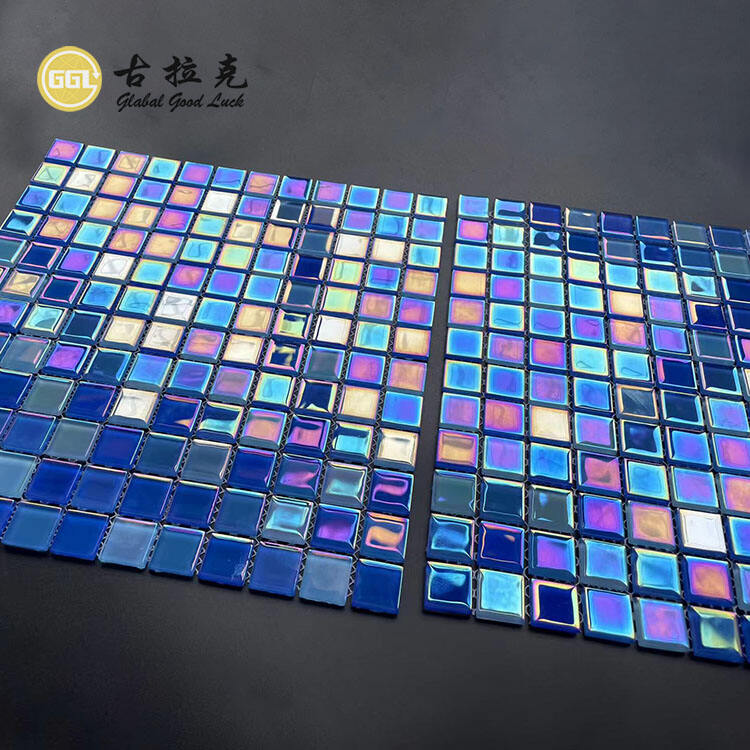

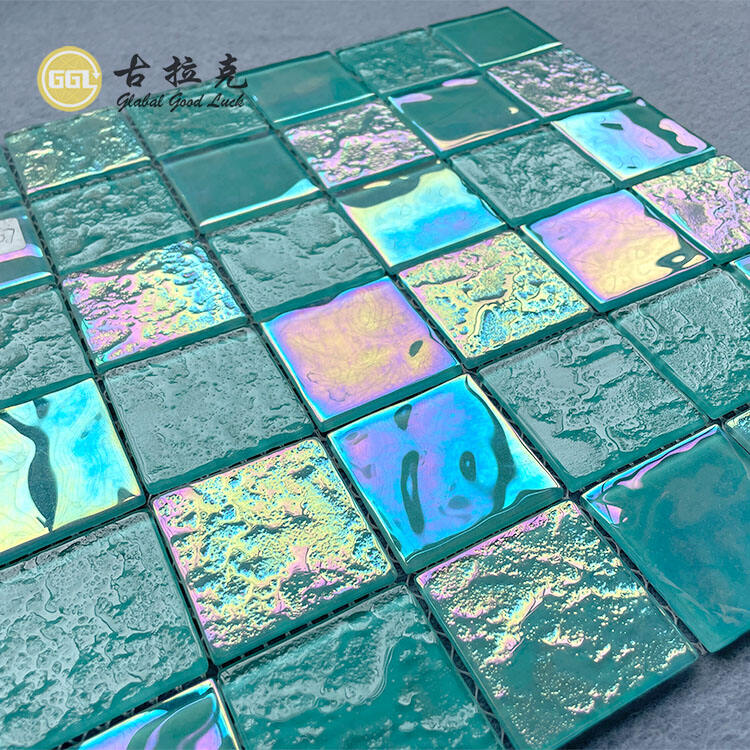

その卓越への献身が認められ、グッドラックビルディングは業界で権威ある賞を受賞しました。モザイクとタイルにおける革新への私たちの取り組み、モザイク用タイル、大理石スラブのアート作品、大理石タイル、そしてクォーツストーンが高く評価されています。当社の世界クラスの大理石ダイニングテーブル、大理石床、プールタイル、大理石のテーブル、ホワイト大理石のカウンタートップなどをお探しください。

さらに表示